-

Home

- About

- Products

-

CNC Lathe

-

High Precision Automatic Lathe

-

CNC Centring Machine

-

Fully Automatic Feeder

-

Turning-Milling Compound Machine

- News

- Agents

- Recruitment

Product CenterClassify

Product CenterClassify- CNC Lathe

- High Precision Automatic Lathe

- CNC Centring Machine

- Fully Automatic Feeder

- Turning-Milling Compound Machine

Turning-Milling Compound Machine

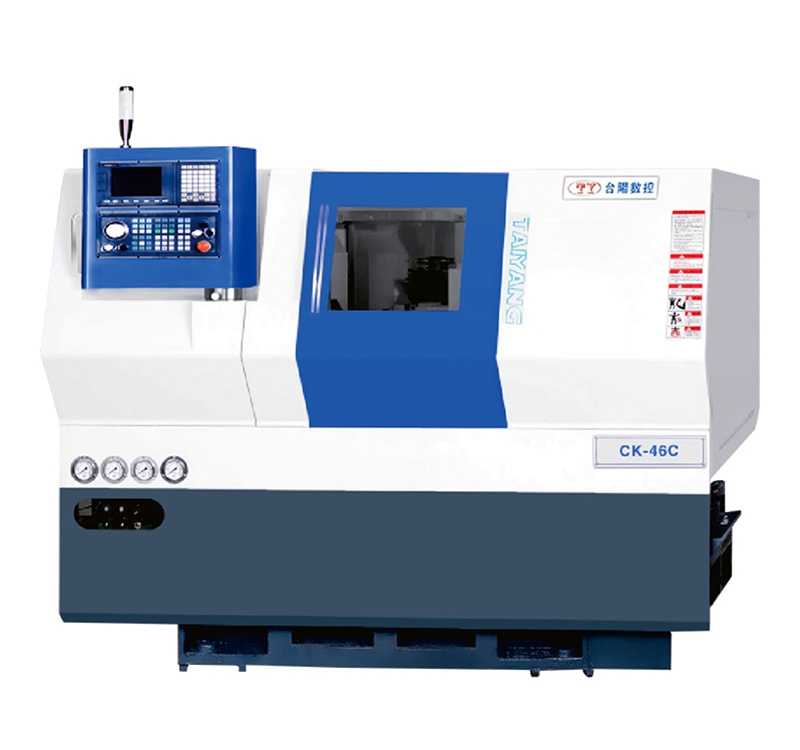

CK-46C/S TWIN-SPINDLE,TWIN-TURRET,SINGLE Y-AXIS

- Type:Turning-Milling Compound Machine

- Code:

-

The CK-46C/S features an innovative "twin-spindle, twin-turret, single Y-axis"layout, ensuring high-efficiency combined machining capabiities whileachieving superior rigidity, stability, and cost control.

1. Efficient Twin-Spindle Synchronization: Enables complete machining of both front and back sides of the workpiece ina single setup, significantly improving precision and efficiency.

2. Upper Turret with Y-Axis: Equipped with Y-axis functionality for precision milling tasks such as off-centermilling and face milling, expanding machining versatility.

3. Rigid Secondary Turret: Dedicated to machining the back side of the workpiece, including tuming.drilling, and tapping, ensuring clear task division and enhanced efficiency.

4. Intelligent Sub-Spindle: Standard features include a parts catcher, spindle ejection, and air blast forchip removal, ensuring smooth and efficient automated production.

Unique Advantages: Compared to dual Y-axis models, the single Y-axis design offers a simplermechanical structure, improved rigidity, and fewer potential failure points, reducingoverall machine cost by approximately 10-20%. With simplified toolpath planningand easier programming and setup, it is particularly beneficial for production cyclecontrol and tool life management. An ideal choice for users seeking exceptionalcost-effectiveness.

- Product Description

Machine Tool Coniguration Model

Item

Standard configuration / Opti onal configuration

System/Driver

Xindai 22TB

Principal axis

Kenturn

Screw rod / Guide rail / Slider

HIWIN

Bearing

NSK

An electical appliance

Schneider

Spindle motor

Xindai

Knife tower

Servo turret (Fengyi turret)

Machine tool parameters/models

Item

CK-46C/S

Unit

Special case

Name

Specifications

First spindle Processing range

Rod through-hole diameter

Push forward φ42/pull back φ46

mm

Processing workpiece length

300

mm

Second spindle Processing range

Rod through-hole diameter

Push forward φ30/pull back φ35

mm

Processing workpiece length

155

mm

X/Y/Z Axis Movement

Z1 axis travel

315

mm

X1 axis travel

165

mm

Y axis travel

±40

mm

Z2 axis travel

335

X2 axis travel

155

Z1/X1/Y/Z2/X2 axis rapid movement rate

25

m/min

Machine precision

Z1/X1/Y/Z2/X2 axis repeatbility accuracy

±0.003

mm

Z1/X1/Y/Z2/X2 axis positioning accuracy

±0.005

mm

Cutterbed

Main Knife Tower

12-station BMT45 servo-powered turret

/

Main Knife Tower handle specifications

Square 25*25/round φ32/power head BMT45

/

Deputy Knife Tower

6-station servo turret

mm

Specifications of secondary turret handle

Square 20*20/round φ25

mm

Spindle

Spindle nose form

A2-5/Spindle through hole φ56

/

Diameter of spindie through hole

A2-4/Spindle through hole φ46

/

Control system

Controller

Xindai 22TB system

set

Spindle motor power

9.5

kw

Auxiliary spindle motor power

3.7

kw

Spindle speed

5000

rpm

X1-axis servomotor power

1.7

kw

Z1-axis servo motor power

1.7

kw

Y-axis servo motor power

2.4

kw

X2-axis servomotor power

1.1

kw

Z2-axis servo motor power

1.7

kw

power head servo motar power

2.6

kw

Size

L*W*H

2300*1660*1830

mm

Special note

1. Remove the second spindle and auxiliary turret, and change the model to CK-46C power vehicle hybrid machine.

2. Remove the second spindle and auxiliary turret, install hydraulic or servo tailstock, and change the machine model to CK-46C/W power milling machine with tailstock.-

About Us

Company Profile Chairmans Speech Culture Honor Patent Enterprise Style Partner -

Products

CNC Lathe High Precision Automatic Lathe CNC Centring Machine Fully Automatic Feeder -

News

Enterprise Dynamics Industry News Common Problem -

Contact Us

Hotline: 4008-166-588 Phone: +86 138 2577 2521 Mr. Xiao Tel: +86 769-81587551 E-mail: 1028423133@qq.com / 13537157072@163.com Add: No.4, Lane 1, Yongkou Hebin Road, Houjie Town,

Dongguan City, Guangdong Province, China Service NetworkMessage

Copyright ©2024 Dongguan Taiyang Precision Machinery Co.,Ltd.Technical support: Tianzhuyun - About