-

Home

- About

- Products

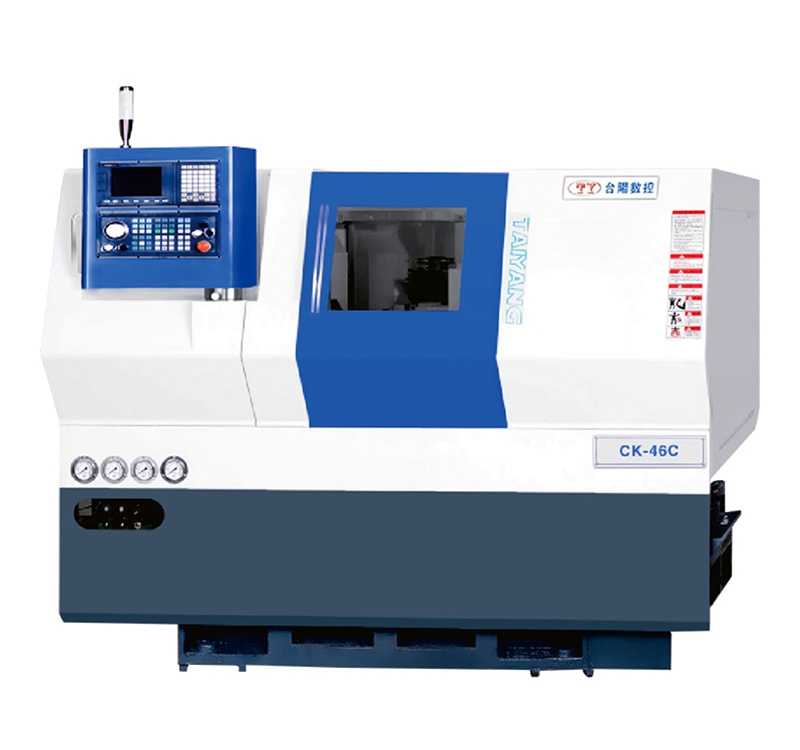

CK-46C/S dual spindle and dual blade tower turning and milling composite machine

- Type:CNC Lathe

- Code:

-

1. The newly designed double-layer structure bed has strong seismic resistance and ensures the stability of accuracy;

2. All guide rails adopt roller guide rails, which enhances the sliding area and further increasesEnhanced rigidity and seismic performance, achieved strong cuttin extended the service life ofthe cutting tool;

3. The 90 degree design of the X and Y axes ensures machining accuracy and machine stability;

4.12 Workstation servo power turret, large gear plate design, stronger rigidity, fast toolchanging speed;

5, The auxiliary turret is a 6-station servo turret with a small turning radius and faster tool changing speed;

6. The first spindle and the second spindle are seamlessly connected, and dual channels are processed simultaneously, thereby achievingHigh technical requirements for complex products;

7. Optional oil or air blowing device for easy cleaning of the chuck, with built-in top material device:

8. Reserve a position for the secondary spindle that allows for the replacement of hydraulic or servo tailstock, providing greater advantages for processing long axis products;

- Product Description

Machine Tool Coniguration Model

Item

Standard configuration / Opti onal configuration

System/Driver

Xindai 22TB

Principal axis

Kenturn

Screw rod / Guide rail / Slider

HIWIN

Bearing

NSK

An electical appliance

Schneider

Spindle motor

Xindai

Knife tower

Servo turret (Fengyi turret)

Machine tool parameters/models

Item

CK-46C/S

Unit

Special case

Name

Specifications

First spindle Processing range

Rod through-hole diameter

Push forward φ42/pull back φ46

mm

Processing workpiece length

300

mm

Second spindle Processing range

Rod through-hole diameter

Push forward φ30/pull back φ35

mm

Processing workpiece length

155

mm

X/Y/Z Axis Movement

Z1 axis travel

315

mm

X1 axis travel

165

mm

Y axis travel

±40

mm

Z2 axis travel

335

X2 axis travel

155

Z1/X1/Y/Z2/X2 axis rapid movement rate

25

m/min

Machine precision

Z1/X1/Y/Z2/X2 axis repeatbility accuracy

±0.003

mm

Z1/X1/Y/Z2/X2 axis positioning accuracy

±0.005

mm

Cutterbed

Main Knife Tower

12-station BMT45 servo-powered turret

/

Main Knife Tower handle specifications

Square 25*25/round φ32/power head BMT45

/

Deputy Knife Tower

6-station servo turret

mm

Specifications of secondary turret handle

Square 20*20/round φ25

mm

Spindle

Spindle nose form

A2-5/Spindle through hole φ56

/

Diameter of spindie through hole

A2-4/Spindle through hole φ46

/

Control system

Controller

Xindai 22TB system

set

Spindle motor power

9.5

kw

Auxiliary spindle motor power

3.7

kw

Spindle speed

5000

rpm

X1-axis servomotor power

1.7

kw

Z1-axis servo motor power

1.7

kw

Y-axis servo motor power

2.4

kw

X2-axis servomotor power

1.1

kw

Z2-axis servo motor power

1.7

kw

power head servo motar power

2.6

kw

Size

L*W*H

2300*1660*1830

mm

Special note

1. Remove the second spindle and auxiliary turret, and change the model to CK-46C power vehicle hybrid machine.

2. Remove the second spindle and auxiliary turret, install hydraulic or servo tailstock, and change the machine model to CK-46C/W power milling machine with tailstock.-

About Us

Company Profile Chairmans Speech Culture Honor Patent Enterprise Style Partner -

Products

CNC Lathe High Precision Automatic Lathe CNC Centring Machine Fully Automatic Feeder -

News

Enterprise Dynamics Industry News Common Problem -

Contact Us

Hotline: 4008-166-588 Phone: +86 138 2577 2521 Mr. Xiao Tel: +86 769-81587551 E-mail: 1045100229@qq.com Add: No.4, Lane 1, Yongkou Hebin Road, Houjie Town,

Dongguan City, Guangdong Province, China Service NetworkMessage

Copyright ©2024 Dongguan Taiyang Precision Machinery Co.,Ltd.Technical support: Tianzhuyun - About